October 2014.

On North Warp, a personal review.

6 years with the Warps.

Important:

This is an advancing review, written gradually as new experiences have

emerged. Consequently, you may find conflicting information. If so, the

latest updates overrule earlier writings.

Some 6 years ago I finally gave up sailing with Neil Pryde race sails. Having sailed the brand for many years I was indeed very happy with the general performance of the sails. Strong in all disciplines and very intuitive and friendly to sail.

But

they certainly had their issues. First of all they were much too

frail - cracking their luff panels, breaking

their top and bottom straps, maculating their extremely complex (but

hard rotating) camber inducers,

breaking their batten tips when de-rigged etc. Oh, and breaking their masts,

probably because of too extreme a luff curve. And on top of that

a culture within the company that always blamed the costumers

for

incorrect

handling of the Neil Pryde equipment when it broke. Evidence of this

sad story can be seen here:

http://peterman.dk/windsurf-NP-RS-series-780gb.htm.

So, no Neil Pryde anymore - but then what? After the Neil Pryde experience the first and foremost criterias were reliability, no-nonsense construction, and back-up from the company. And if these qualities came at a price (in terms of money or reduced performance), then so be it. I was looking for contrasts to my Neil Pryde era.

The arrow quickly

pointed at Northsails. North has a reputation of making quality products

that are tested out and that are backed up

by

fine guarantees. As to the sails North seems

to be rather conservative

with not too many "breakthroughs" (good!). And

where their

corporate

culture

is concerned

they seem

to

have a more

European (German-Austrian)

attitude

than

an

American/Far

Eastern attitude, which

we've come to associate with

un-reliability, empty words and strict

cost-benefit focus. Well at least

that were

the expectations of me and my son,

who joined

me in my

switch

to

North Sails.

Experiences with the Warp sails.

Just to clarify: We're certainly no slalom racers. What we do, I guess, can best be described as "freeracing". That is sailing with our surf buddies, covering relative large areas (long legs of upwind, downwind and beam reaches) in a variety of sea conditions and wind strengths - and where the main objective is simply to not be the slowest guy on the water. Jibes are mostly necessary evils that often turn into pure punishment.

If you're curious

about

our

(moderate)

level and way of

sailing, here are a couple of videos

to give you an idea:

https://vimeo.com/album/2851238/video/73816539,

https://vimeo.com/album/2851238/video/71924037, (and more here:

https://vimeo.com/album/2851238).

Our

evaluation of the

Warps are of course subjective and in no way the result of structured,

comparative testing.

Durability.

None of our (almost

20) Warp sails have had any of the fatal faults with cracked luffs that

haunt the Neil Pryde race sails (and to a lesser degree a couple

of other brands we've had

short experiences with,

for instance Severne Reflex

II). The closest we've come to that fault was a

North Ram from 2008 that cracked in the luff panel a year and a half

from the date of

purchase. And

for

that sail,

repair was not "offered" within

a couple of months (as is

common

practice in my country for Neil Pryde sails -

if

the sail is less than 6 months old!). No, the sail was

immediately replaced with a new Ram model 2010. But

like I said: No

such issues with the Warps.

The only complaint

we've had

about

the durability of the sails turned up this spring,

when the bottom camber on my Warp 9.2 F2013 refused to rotate.

Upon

examination it

turned out

that the batten had penetrated the batten pocket

and jammed against

the mast through the camber inducer.

The

warranty "offer"

from the North

company was not that

impressive (50 Euros to have it repaired at a

sail loft), so I

respectfully declined and

found a way to repair it myself. What happened to

the 5 years warranty ... !?

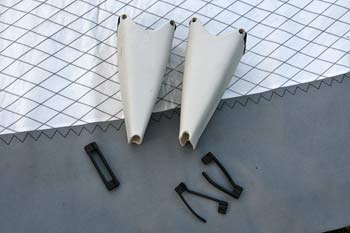

The bottom camber in the F2013

9.2 refused to rotate. With the

camber removed it's obvious why.

Click the picture to enlarge.

Only in no-cam sails have I witnessed

the batten running out through the

batten pocket after rubbing against

the mast. Here there was no rubbing.

Click the picture to enlarge.

A kind of solution: Fixing a batten

pocket end from an old "Reactor

Bar."

Click the picture to enlarge.

The new batten pocket end is exactly

narrow enough to squeeze inside the

camber. With guarantee that the problem

won't ever be coming back.

Click the picture to enlarge.

I'm still

a bit puzzled about the damaged

batten pocket, as the tip of the pocket never touched he mast.

The hole

in the batten pocket tip consequently wasn't the result of wear by

rubbing against the mast.

I suspect

that generally the F2013 Warps are built a little more flimsily than

normal North standard, and that this is reflected by the mere 2 years warranty for

F2013s in contrast to the normal 5 years warranty for all other Warps.

Never mind,

on the

whole

this has been our only complaint

about the durability/craftsmanship of the Warps.

Bottom cambers are pretty

tough to polyamide coating of the masts, so the masts have to be strengthened from time to

time with a little resin filled glass- or carbon weave. I recon that

this little issue isn't a problem for North alone.

After long time of use (years) the relatively soft plastics

of the cams show sign of wear (the camber to the right).

If you use a spacer shim in an already deformed

camber, it'll break.

Compare to the new camber and shim to the left.

Click the picture to enlarge.

It takes a long time before the cambers wear out and

need to be replaced. But then, why the necessity for

all my spare cambers, you'll perhaps wonder.

The reason is simply that every time a Platinum mast

breaks inside a Warp, it splits open the mast pocket

- and at least one (most often two) cambers disappear

into the sea.

Click the picture to enlarge.

Performance.

As stated: We didn't

convert to North Warp

for reasons of

performance. And to be honest, generally the North Warps

have their own distinct "taste" compared to the majority of race sails

from other brands. Let's break up the picture a little:

The pros.

1. Superior camber

rotation.

The Warps have

always (well, at least the last 6 years) been trendsetter in effortless

rotation. Compared to other race sails the cams (the "hypercams" that

is) have a no-nonsense design, they are made from relatively soft

plastics,

and the rollers are placed in front of the cambers. To

my

knowledge, there are no

downsides

to

this design - for instance the profile

stability is at least as good as the competitors'.

2. Very good top

speed.

The speed in high

(and partly in medium) winds is very good, at least if you have the

power/weight to handle the sail. So, at least

on flat water you can make

some very fast runs.

3. Great profile

stability.

Also, the stability

of the profile is extremely good. In fact we've very seldom (if ever)

experienced a problem with an

overpowered Warp per se. When we've felt overpowered the problems have

almost always been with

the rider

(not having the power/weight to tame the sail) or the design/trim of the

fin or board, resulting

in tail walking or not managing the chop convincingly.

4. Explosive acceleration in high winds.

This is the positive side of the very direct feel you have with the Warps. No doubt that if you have plenty of wind and keep sheeting in the Warp during the first meters of planing, it'll reward you with serious speed very quickly. Don't expect the Warp to dampen the power.

5. Very light weight

(static).

The static light

weight of the Warps have been paramount to the competitors the last

several years - partly because of the 7 battens

design. And the

dynamic feel of the Warp is also pretty good. The lack of "grunt" helps

in this respect, while the directness and nervousness retracts a little.

The cons.

1. Poor low end

power.

Poor planing

ability, poor pumpability, lack of low end power and only moderate speed

in light winds are Warp (and generally other sails from North)

characteristics. Sail designs are

the result

of certain choices, and

apparently some choices

are mutually exclusive. It's pretty obvious

that some Warp-qualities (very stiff and rigid with

comparable

shallow profile) don't leave room for the Warps to excel in low winds. And

North knows what the main

complaint has always been: Every year

for the last 6-7

years,

the presentations of the next year Warp have

claimed that NOW North

has addressed the very same low-end problem. Have a look:

2009:

"Better acceleration" obtained by "lower tension for the mast sleeve

area ..."

2010:

"Better acceleration and pull", obtained by "deeper profile ..."

2011:

"Better acceleration", obtained by "tweaked profile ..."

2012:

"Maximum acceleration", obtained by "fuller profile ..."

2013:

"Improved low-end acceleration and pumpability", obtained by "deeper

profile and higher flexibility ..."

2014:

"Low-end power and acceleration", obtained by "increased profile in the

upper luff area ..."

2015:

"More low-end power and pumping ability", obtained by "reduced luff

curve ..."

The funny thing is,

that in spite of all these

claimed efforts the Warps have never excelled in the low end

disciplines

in (for instance) the Planchemag

magazine slalom sail

tests over the years (see

links below).

If North really thinks the

Warps

have been improved

in this respect -

then the

competitors have improved more. Maybe the F2015

will

prove to be an exception,

but the need of a special LW 9.0 in the line up may be indicative of

otherwise ...

*) This is the last few lines from a "micro-test express" of the all new Warp F2015 7.7 in Planchemag. No. 367, Oct/Nov. 2014:

"The F2015 7.7 is very balanced, with a little more power to the back hand than last year. The passage of the cams is probably the best in the market. A stiff sail, that are more nervous than most others."

Seems that the Warp F2015 stick to the same distinct Warp character that we've come to know from the previous years. But perhaps a little more low end power?

We feel that

the

Warp

with the best low end performance

has been the F2012, followed by the F2013.

Unfortunately the (generally very good) F2012 is probably also the

stiffest sail of the lot, having a massive (and mast-breaking!) luff

curve.

2. Questionable control, unless you're a heavyweight.

If you think that

the very fine profile stability of the Warps results in good control,

you'll probably be disappointed. That is, at least if you're not a

heavyweight. For

riders under approx. 85 kg the

stiffness/directness/nervousness of the Warps (sailed with the Platinum

masts) are so overwhelming that you'll have a hard time controlling it

in high winds, especially in chop. It simply feels that the Warps dump

the power too late for the

sub-85

kg

riders.

For several years some sizes of the Warps were recommended with 30 cm longer masts than the competitors. So, until the F2013 Warps you had the opportunity to rig some of your Warps with shorter (= softer and slightly more relatively Flex Top, se this study: http://peterman.dk/windsurf-NP-X6-mast-study-780gb.htm) masts than were recommended. For instance, you could rig your Warp 7.0 with a 430 cm mast instead of the recommended 460 cm mast - or you could rig your Warp 7.8 with a 460 cm mast instead of the recommended 490 cm mast - or you could rig your Warp 9.3 with a 490 cm mast instead of the recommended 520 cm mast. My son (approx. 60 kg) and I (approx. 80 kg) have mostly rigged our Warps on the smallest masts possible, just to have a chance to survive in really high winds and chop. But as the latest Warps (F2014 and on ...) are now generally recommended with as short masts as the competitors, that possibility no longer exists (except for the 7.0).

In our view the most

controllable Warp has been the F2013, closely followed by the F2012.

In the other end

we find

the F2011, that we've

judged to have a

pretty narrow area of use.

Why this distinct performance character of the Warps?

I'm a little curious

why North hasn't addressed the combination of questionable

controllability (for lighter sailors) and poor low end power. Is it

because the boards North test their sails with are very controllable and

early planing boards (for instance the Starboard iSonic series), so that

the performance character of the Warps

is

not noticeable for the

developers and

testing crew? No, in fact the North Warps seem to be

tested with the Fanatic Falcon series (also from the Boards & More

company),

which has a reputation of fine

top speed, but was never

known for early planing or controllability (possibly because of designer Wenzels love for tail kicks and

relatively short

flats).

So,

I'm still curious why the Warps year after year are biased towards this

unforgiving stiffness/directness/nervousness and

poor low-end power. As

indicated it seems that the sail performance characteristics of

North Warp are in line with the board performance characteristics of the

Fanatic Falcon. A Boards & More philosophy?

For the F2015

Warps,

North

says: "On water and comparison tests have shown that there can be "too

much" power and acceleration. If this is the case, the rider is

struggling so much with the rig that the optimum rake, an acceptable

handling and efficient transmission of the sail power into board speed

are no longer guaranteed. Loss of speed and control are the result.

Therefore designer

Kai Hopf has found the perfect balance between maximum acceleration and

optimum control when overpowered for each size of the new range,

matching the weight of the prototypical PWA slalom racer (between 90 and

100 kg)."

As I read the

statement,

North finally admits that the Warps generally have been a handful to

control near the upper wind limit - and that

acknowledgement

is definitely a

first step towards designing a more friendly race sail. However, the

last part of the statement completely ruins this prospect for the

not-so-heavy sailors.

Riders under 90 kg

will

apparently still feel the overwhelming stiffness/directness/nervousness

of the Warps. And you

no

longer have the option to rig the Warps with shorter

(=softer) masts than

recommended, as North now (as said) actually recommend relatively short

masts, in line with the competitors.

A wish.

Now that

it's no longer

possible to rig the Warps with shorter masts it might perhaps be a good

idea for North to learn from Loftsails. Here you

have the option to rig the race sails (Racing Blade) on RDM masts, if

you aren't a heavyweight and prefer a softer sail. Apparently the

Loftsails Racing Blade (above 6.3

square

meters) are delivered with cams that

fit

both

SDM and RDM masts. With the Warps being so stiff and

(declared to be) designed for the heavyweights, why not offer a RDM option

for lighter sailors?

Oh, a

A note on the trim

The F2009, F2010 and

F2011 we always had to rig with a very low placement of the boom. This

was the only way we could hold the nose of the board down and keep the

foot placed firmly in the front strap. Then suddenly, on the

relatively powerful

F2012 and F2013 we could raise the boom to "normal height" and still have a

fast and

controllable board feel

(we've

always ridden

boards from the RRD

X-Fire series).

However, that feel

totally disappeared again with our only Warp F2014 (a 7.8). Compared to

the Warp F2012 and F2013,

which were both fine performance-wise, our F2014 7.8 was a

disaster, and after

a few sessions on the water we gave it up.

Frankly, I

had to humiliate myself

by asking a windsurf buddy,

to

whom

I had given my old

F2012 7.8

(with several scars from

breaking masts),

to have it back - and compensate him with another Warp from

our surplus stock. We simply couldn't trim the F2014 - and I suspect

that

(apart from our lack of

ability)

it was the pretty odd design with more profile above the boom that

destroyed the trim. When measured and compared to

our F2012

7.8,

the F2014 7.8

has the profile placed a little more forward, and measured on the 3

lowest battens it had up to 1,5 cm less profile, while measured

on the two next battens it had up to 1,5 cm more profile depth.

Perhaps an even more Flex Top like mast than the 460 cm Platinum 2014

mast could have saved the trim of the sail?

Anyway, we gave up the sail that felt delicate and strangely "flimsy" to sail. It also felt a bit smaller than the previous Warp 7.8's, and as such it was difficult to fit into symmetric into the space between our Warp 8.6 (F2012) and the Warp 7.0 (also F2012). I don't know if North continues down this new road of design. Buying a new race sail is a lot about faith to the people around the designing process (you cannot have a test drive and when the magasines publish their tests its most often too late to order the sail).

NOTE/HENVISNING TIL SPECIEL SIDE: Probably unfair, but I'll have to say that the inclusion of Dani Aeberli in the North design team (and in the Fanatic team as well) might indicate fashion over sober designing. Have a look at this masterpiece from Dani Aeberli: . Hope not that this is the kind of ....that'll be built into the Warps in the years to come ...

We quickly gave up the Warp F2014 7.8 and althoug our quiver badly needs FORNYELSE we decided not to invest in any Warp F2015 sizes. Hopefully the UDVISTE performance of the

| Profiles along the battens. | ||||

| Warp 7.8 2012 | Warp 7.8 2014 | |||

| Draft | Depth | Draft | Depth | |

| position, cm | of draft, cm | position, cm | of draft, cm | |

| Batten 1 (lowest)) | 45 | 18,5 | 44 | 18,1 |

| Batten 2 | 57 | 23,4 | 53 | 22 |

| Batten 3 | 52 | 18,7 | 50 | 18,3 |

| Batten 4 | 42 | 9,1 | 35 | 10,5 |

| Batten 5 | 25 | 4,2 | 27 | 4,7 |

I simply couldn't figure out why I found the F2014 7.8 to

be such a lousy sail compared to the F2012 7.8 (and

the F2013 7.8 for that matter).

Here both sails are rigged with Platinum masts with

exactly the same stiffness and bend curves. It's not

easy to measure the profiles of the sails, but it

was given a try (see the numbers to the left).

Click the picture to enlarge.

Here are some links

to

what the French Planchemag magazine test crew thinks about the

performances of the

past

4 years of Warp sails:

F2011:

http://peterman.dk/windsurf-mag-dk-900-slalomsejl2011-70-71.htm.

F2012:

http://peterman.dk/windsurf-pro-mag-dk-900-racesejl-78m-01.html.

F2013:

http://peterman.dk/windsurf-mag-dk-1200-slalomsejl-76-79-01.htm.

F2014:

http://peterman.dk/windsurf-mag-dk-900-slalomsejl2014-77-79.htm.

Experiences with the Platinum masts.

Bend characteristics of the Platinum masts.

I remember from the

Cold War a theory about "convergence" between the two antagonistic types

of society.

In the Cold War

this convergence never really materialized, but in a totally

different ballgame

- the bend curves of windsurf masts - it's fair to talk about the mast

schools coming closer together. Proponents from the Hard Top school

(Barry Spanier/Phill McGain from (now) Maui Sails) have "adjusted" their

race masts to be Constant Curve, and so

too does

Gaastra

seem to have done in incremental steps. I'm a little more in doubt about

the race masts of Severne - but I suspect

that

the brand has followed the route of MS and Gaastra. Otherwise Severne

shall be pretty isolated.

In the opposite end of mast bend thinking, Neil Pryde stepped a little back from the extreme Flex Top idea a long time ago (since the Race Pro masts). But for several years NP has still been the leader of the stiff bottom section/soft top section philosophy (the smaller masts intended to be most Flex Top like). That's no longer the case: At least some brands have adapted (or perhaps even overtaken) the position of Neil Pryde these past years. And among these are North (Gun and probably others) with the Platinum series. Latest measurings of mast bend curves indicate that Norths race masts have catched up (overtaken?) the race masts from Neil Pryde in terms of having a relatively soft top section of the masts.

So forget about

North's Platinum masts being Constant Curve (bend curve 10-12). Platinum

masts are (very close to) Flex Top (16-18). When measured, the

latest 2014

Platinum 490 cm mast had a bend curve of 17.8!

At least this size Platinum mast

must now be

a

kind of

market leader

when we talk about Flex Top masts.

Why this general move towards relatively softer top sections/stiffer bottom sections?

In

marketing stuff

you often

hear the

different brands

saying that they have designed the bend curves of

the masts to meet the needs

of their race sails.

In general, that's perhaps not

true

any longer. Because of the massive breaking

problems of the race masts

that several brands have faced, it seems that

an increasing number of

brands now

design their race sails to fit the strength of the masts, just to

obtain a minimum of durability.

Masts generally don't break by over stretching the fibers on the outside bend curve of the masts, they mostly break by compression of the fibers on the inside of the bend curve. And since glass fibers are stronger in this respect than carbon fibers, some race masts now have glass fiber layers outside the carbon layers - at least on the bottom sections of the race masts. Sail designer Robert Stroj from Neil Pryde goes into details.

So, the bottom sections

of the race masts have

been "beefed" up - and the bend curves change

in the direction of relatively softer top sections/stiffer

bottom sections (= being more Flex Top).

Platinum

masts have been

breaking - a lot!

At least until recently, North has had some massive breaking problems with at least some of the Platinum masts. To deal with the breaking problems North (or perhaps more correctly Italica, the mast producer) has wrapped on some polyamide coating, adding sun protection and preventing scratches from cams, booms etc.). The masts have been beefed up by increasing the wall thickness by adding more carbon layers and ostensibly changed the carbon structure, and some glass weave (called Alutex) has also been wrapped to the bottom section. Finally North has declared that the luff curve of the larger sizes of the Warp F2015 will be reduced.

All the efforts to make more durable masts have added to the weight of the Platinum masts, but probably only to the bottom section where it can't be felt so much. And honestly, you can easily live with a weight increase - if only the mast doesn't break.

It has

yet to be seen

whether things

will

change

for the future

Platinum

masts. If you accept

the special feel and performance characteristics of the Warps, the only

big (and that

has been

very big)

issue with the Warp sails

has been the extreme mast breaking rate of

at least some of

the dedicated

North Platinum masts.

Apparently the horrific Platinum breaking rate has led

someone with enterprise (or humour?) to sell special

"Survival knives for Platinum mast breakage".

Click the picture to enlarge.

Close-up of a "Platinum survival knife". In fact it's no stupid

idea to bring with you such a folding knife on the water.

When a mast breaks, one of the hurdles is to untie

all the knots, downhauls and outhauls so you can pack

the gear and paddle back to the beach. Cutting the lines

is a lot easier and very time saving.

Click the picture to enlarge.

Conclusions and experiences

with the company.

Like I said, I

switched

away from Neil Pryde primarily because of the seemingly endless lack of

durability, and because I as a costumer was always blamed for

mishandling the sails, when they fell apart.

Did the shift

away

from

Neil Pryde race sails to North Warps help in these respects?

Regarding the

durability...

Very durable

Warps, but

the

breaking Platinum

masts

has

turned them into very fragile rigs.

The Warps per se

definitely are much, much more durable than the Neil Pryde race sails.

The craftsmanship, the choice of (light!) quality materials and the

no-nonsense design with simple/strong cams, batten tensioners, pulleys

etc. guarantee day after day sailing without having to send the sails to the

sail loft for repair - or to the scrapheap.

Furthermore, North

backs up their products with very fine warranty conditions. On most Warps,

North offer

a

5 year warranty, but

only the normal 2 years on Warp F2013. This warranty doesn't include

cracking monofilm,

nor

apparently

(as

mentioned

above)

defects in batten pockets. But generally,

they have a warranty policy

that is second to none in the windsurf business.

With regards to masts, you have the opportunity to have a 2 years unconditional warranty on Platinum masts (but not Gold masts), if you fill out a warranty registration. This is a unique offer in the industry, and apart from communicating the trust North has to their Platinum masts, there has been a historic reason for the offer. We certainly have been registering our Platinum masts, and I must say that until recently we've been using the 2 years unconditional warranty a lot - especially for the 490 cm Platinums.

And

that has been the snake

in the grass: Some of the Platinum masts. But

you might think:

that's "just" a mast problem. NO, in fact it quickly turns into a

Warp

durability issue too. When the Platinum mast breaks (mostly just above

the boom, but

occasionally also below the boom or in the ferule area),

as a

minimum it also breaks out through the

sleeve

- and if you're

unlucky

it

completely

ruins your Warp. The North warranty only gives you a

chance to have the broken Platinum mast replaced.

There's

no chance that North

will

replace the destroyed Warp or pay for a repair. And of course, forget

about compensation for the

lack of resale value.

Most Platinum masts break

just above the boom, but

the masts keep surprising you. This one gave up in

the ferule area.

Click the picture to enlarge.

This Platinum mast broke the

normal way - just above the

boom. And just as normal

is the "collateral damage"

- a split open

sleeve.

Click the picture to enlarge.

A long time ago I gave up sending

the Warps with destroyed sleeves

to the sail loft. In accumulation

it was simply too costly.

Repairing a sleeve by hand

(with contact cement, leather

string and holes made by a

very thin soldering iron)

normally takes 3-8

hours. Cheap, but the

resale value is totally

gone.

Click the picture to enlarge.

The result of another DIY

repair after yet another

Platinum breakdown.

Click the picture to enlarge.

In fact, you

probably

can't blame

only the Platinum mast itself

for

breaking and

all the consequences thereof: When rigging the Warps with masts

from other companies (and mast producers), the masts still break in the

Warps. I haven't got the statistics

to show that "foreign" masts break

in the Warps at the same alarming rate as the Platinum masts

have done - but

they do definitely break.

The problem seems to

be that,

in search of ultimate performance, the Warps have some extreme

luff curves that give the

masts a hard work. In fact, our

favorite Warps (performance wise) - the F2012

(and F2013)

- have

also eaten

the

most masts by far.

Warps from other years have also been hungry for

masts (we haven't had any experiences with

the F2014, as we

quickly

dumped our 7.8

due to odd trim), but the F2012's were the most gluttonous. I guess

that

a substantial cause (tough luff

curve) for

the extreme breaking

rate has

led to

this

promise by North

regarding the F2015

Warps

sizes 8.4 and up: "... the luff curve got reduced."

A promise that apparently doesn't include the 7.8 (according

to our experiences a mast breaking size

too!) and down.

So, durability-wise

some

Platinum masts sizes have been the

Achilles' heel

of the Warps,

and until North proves

that the Platinum mast breaking

problem is history, I'll hesitate to call the Warps (as part of the rig package) durable. But w

Regarding the company ...

North

is a

major

brand with a fine reputation of backing up their

products.

But there are exceptions:

In the spring 2013 a couple of our new Platinums 490 cm masts literally started braking around us. When addressing the importer we were told that Boards & More had informed that "there has been a failure on a production of 490 Platinum masts" (translated from Danish).

As we still had a new 490 cm Platinum masts left that hadn't broken yet, we (urged by our retailer, in fact) asked the imported if we could have it substituted with a specimen from a no-failure production. No need to experience a mast breaking on the water with all the implications (destroying the sail, a long and risky swim/paddling back to the shore, etc.), we thought.

But apparently the policy of North was to wait for the masts to break - not notifying people about the problems - and only send the costumers new masts when the socalled "failure production" masts broke and people reacted. North answered:

"We cannot replace a mast before it is broken. Please note not every Platinum

mast is breaking because of low serial number. Thanks for understanding."

I suspect that it

was

this questionable behavior

from North that was referred to in

this interview

on windsurf right-of-law in the German "surf" mag. from August 2014

(the relevant words marked with blue).

I have to praise the willingness of the product manager,

Raoul Joa, to answer your questions in depth. It's been a while since

I've addressed Raoul Joa, and I don't know if he's still around at

North. If he is, and if you have serious questions about the North

products, you'll probably get very honest answers from Raoul -

answers that are miles away from the sales babble you much too often get

from most other brands and

their team sailors(!). And if he asks for a little discretion in his

answers, that's the least you can do.

A company for the windsurfers or the shareholders?

The "corporate

cultures"

within the businesses for windsurf gear

probably moves towards a

global, universal short sighted, pure commercial way of thinking and

acting. I mean, the companies

of course

try to make us think that

their primary goal is to

develop

windsurf gear for the windsurfers

in love with windsurfing.

In reality, it's perhaps more

likely that it's

purely

about business,

and that

the companies

don't give a damn if

what they're developing, producing and selling

is windsurf

gear or chopped pork.

But of course there is room for variation, and the more we as windsurfers/costumers take decent behaviors of the companies into our considerations when choosing a brand, the more room for variety. I mean, there's a tendency to talk about "development" as something objective outside our control - often without wondering who is (also) driving the "development". We (the costumers and users of the products) are a driving force with our freedom to put feelings into our choices at the expense of more cynical incentives. We still have the option to not only hunt for the best products at the lowest prices - but to be guided by stupid concepts like, for instance, "sympathy".

Perhaps a little naive,

I still find at least some difference between North and for instance

Neil Pryde. If there is, in

fact, no difference in the

substance,

then I

will congratulate North for having been able to give me that

impression.

|

Warps

for the future? A personal note on race sail brand decision

making.

Unfortunately, choice of race sail brand from a performance

perspective is not so much about facts as about feelings and

trust to

the

designers, the design process and promo words. Why's

that? Well, except from a very few brands (Gun Sails?) you can't

go through the normal buying process when it comes to new race

sails. It's not like buying a car, where you can collect all the

information you like before actually deciding (reading the

specifications, examining others views, reading tests results,

having a test ride ... etc).

If

you decide that you need a couple of new race sails for

the coming season, you'll have to order the sails

from the retail

shop/the importer averaging 3 months before delivery (in my

country). The time when you could actually see and touch the

sails before ordering, and when you could learn from tests and

people around you how the sails performed, is long gone.

Generally the shops no longer have stocks of race sails to

choose from.

At the time

in the developing process when you have to order, you barely

know the specifications of the race sail. Often you'll have to

guess about the exact sizing (is it a 7.8 - or a 7.6 or a 7.9

for the next year?), you don't know if there's a change in masts

(recommended lengths, bend curves) or boom lengths (more or less

cut out?) than last years model - changes that might force you

to buy new hardware in addition to the sails. And what about the

design parameters - dare you rely on the declarations of intent

about more control, more power, softer handling etc.? And the

important magazine tests? Forget it - the magazine tests are

published looong after the deadline for ordering the sails. The

function of magazine tests these days is to give you a hint if

the sails you ordered 3 months ago are competitive sails or

doors.

The point is

that ordering new race sails is all about

confidence and

trust - in the

absence of the possibility of having the sails in your hands or

learning from the experiences of other sailors. And having to

trust the will, ability and words of designers and marketing

people of course opens for many relevant and irrelevant

speculations, as you're left in a twilight of uncertainty. In

the case of the future North Warps you might for instance

speculate ...

1. Are you

confident that the traditional Warp design peculiarities are a

sound a base for a competitive sail? For instance:

- By a

fair

margin the Warps traditionally have the smallest cut outs among

the race sails from various brands. Is this a deliberate choice

- or is it because the profile for whatever reason is designed

so stiff that a larger cut out would be counter-productive?

Speculations that are probably wrong ...

- The Warps

for several years have sticked to the 7 battens concept - while

the race sails from other brands mostly have 8 or even 9

battens. Is there a reason why other brands mostly opt for more

battens - for instance that this allows them to use less seam

shaping, for the benefit of a softer and more forgiving feel?

Does the Warp 7 battens concept so to speak lock the sails to a

stiff, unforgiving feel with little possibility to design a

damp, early planing sail? Speculations that are probably wrong

...

2. Is it

productive for your confidence in the Warp concept that you

several years in a row have been promised that NOW the new Warps

shall have competitive low end power - but that you exactly the

same number of years in a row have had to accept that this was

yet another unfulfilled promise.

3. Have you

faith in the people designing the Warps. What about Kai Hopf?

He's obviously following his own design route - but is this a

sign of an ability to design state of the art race sails - or is

it a sign of not being able to catch up with designers from

other brands, designers that the last several years have

launched race sails that generally have been higher valued by

magazine testers than the North Warps? And what about this new

man - Daniel Aeberli - that seems to be placed in the slot between

the designer and the international sailors (testers?) in both

North and Fanatic. What's his qualifications? Is he a guy with

drive and knowledge, or is he merely a smiling marketing guy?

This product from

his personal fin brand perhaps isn't too promising.

Again -

speculations that are probably wrong and unfair. But speculations

caused from having to decide which race sails to order with no

actually knowledge. And the less you know, the more paranoia ...

For me personally - also in the light in of my (to be nice) mixed experience with my latest Warp F2014 7.8 - I've decided not to buy any new Warps for the 2015 season. If the magazine tests of the F2015 Warps indicate that the Warps are catching up with the race sails from the other brands (performance wise and as to user friendliness in particular) I'll renew my quiver with new Warps in 2016 (I've got a lot of Platinum masts that can't be used with much other brands!). But if the magazine tests indicate that nothing has happened I'll probably switch to another brand in 2016. GA Vapor and Loftsails Racing Blade have been tested to be very balanced and friendly/comfortable sails for a couple of years - but so has the Gun Sails GS-R to some degree. And the GS-R has the advantage of at least having a chance to fit my later very Flex Top like Platinum 490 cm masts - as probably the only race sail brand on the market!

Update March 2015:

The

Planchemag Spécial Tests 2015 just arrived, and a quick look at

the slalom sail department ("Voiles de course 7,6-7,9 square

meters") confirms the worst expectations. Seemingly the North

Warp F2015 7.7 is even more peculiar than the Warps of the last

couple of years. In short it's the same old story - but perhaps

even worse: Top rates in lightness and rotation, but extremely

stiff and direct

(a big problem in chop, as

I understand)

with the worst rates in early planing and

control among the tested sails.

As said

elsewhere, according to North's description of the Warp F2015,

North seems to be well aware of the classic Warp performance

problems (late planing, lack of control and much to much

stiffness). Cite from http://www.north-windsurf.com/: "...

designer Kai Hopf has found the perfect balance between maximum

acceleration and optimum control when overpowered ... (the Warp

F2015 is) even more

powerful and much more flexible."

Sorry to say,

but if the 2015 test in Planchemag shows a right picture of the

Warp F2015, there's a huge gap between what the designer has

tried to achieve and what he has in fact been able to come up

with. And especially the two worst rankings are puzzling:

Normally the it seems to be highly problematic for the designers

to combine good rates in the Early Planing performance

and in the Control performance. If you score high on

Early Planing, you tend to score lower on Control - and vice

versa. And in the Planchemag 2015 test no brand succeed to score

highest rate in these two performance categories (closest are

Gaastra Vapor (9 and 10 respectively), Loftsails Racing Blade

(10 and 9) and Neil Pryde RS Racing (9.5 and 9.5). But what

about the North Warp? Pretty sensational the Warp scores the

worst rates in the test in both Early Planing and in

Control. That must be almost as difficult as to score high in

both performance categories!

Does this

make the new Warps to bad race sails. Of course not, in the

right hands the Warps can - and will - probably win races in

2015. But for us

ordinary mortals it'll be very tempting to seek the

brands making race sails that perform better AND are easier and

more friendly to sail.

What a pity that the people capable of making sails of a very high standard (durable wise) apparently haven't got the ability to design competitive slalom sails (performance wise) for sailors on a non-PWA level.

|

Update October/November 2015.

1.

More on mast breakings, the causes and sail durability.

Remember I

said that our F2012 Warps are the best performing Warps we've

had? Better than earlier Warps and better than later Warps. The

fact is that the very good performance of the F2012 Warp series

first and foremost seems to be a result of a very, very strong

luff curve that stabilizes the sails better than any other Warps

(in my view). However this luff curve comes at a price - and the

price is lack of durability. Durability for the masts and - very

seldom - durability of the sail.

It's no

secret that the very strong F2012 luff curve breaks a lot of

masts. My Warp F2012 8.6 alone has cost me 4 Platinum 490 masts

with a 3 times destroyed mast pocket when the masts broke out

through the sleeve.

I've noticed

a (potentially) very interesting phenomenon regarding the mast

breakings in this particular sail: The 4 masts broke in 4

distinct different spots in the sleeve: One in the boom cut out,

one just above the boom cut out, one further up the sleeve and

one yet further up the sleeve. Every time the masts broke out

through the original stitching of the sleeve at the same side of

the sail. Afterwards, the broken stitching was repaired (very

durable!)

by hand using

a

soldering iron and leather string,

totally without considering the resale value.

But why

haven't the masts broken out

through the sleeve at the same spot

twice? Why have the masts "chosen" a new and

not-strengthened/repaired spot to break out through? A

coincidence, or ...? What if the order isn't 1) mast breaking,

2) destroyed stitching? Isn't it feasible that the order is 1)

the very strong pre-bending of the mast (over-)loads the

stitching of the sleeve and makes it give up, and 2) the mast -

not being supported by the sleeve at the torn spot - is point

loaded and breaks.

This could

explain why the masts haven't been breaking at the same spot

twice, because the break-out spots on the sleeve are later

strengthened by the strong repairs. Probably not the whole truth

about the mast breakings in my Warp F2012 8.6. But perhaps part

of the truth?

The Warp F2012 8.6 has

"consumed" 4 Platinum 490 cm

masts. All masts have broken

in a not-reinforced (= repaired)

spot. Was it in fact a weak

sleeve (bad stitching) that

caused the masts to break?

Click the pictures to enlarge.

The strong

luff curve of the Warp F2012 is probably the reason why the luff

of my Warp F2012 8.6 has cracked. This certainly isn't a normal

incident for the Warps (as it is for other brands, guess who?).

But when a luff cracks in a Warp it's kind of logical

that it happens in a Warp F2012.

Luckily, I

noticed the crack before it spread through the whole luff, so it

was relatively easy to repair (I've got a lot of experience in

the luff repairing business from

helping myself and my

windsurf buddies with our cracked Neil Pryde RS

Racings). I didn't report the cracked luff to North, as I've

learnt from earlier incidents that the 5 year warranty often

means a 50 Euros contribution to have the sail repaired at a

sail loft. At least in my country a sail loft will probably not

even open the sleeve for 50 Euros! Furthermore, it's my

experience that it's pretty seldom that sail lofts succeed in

repairing a cracked luff in a lasting way. I suspect that the

demand

from some costumers for an aesthetic

repair is the main reason for the bad statistics.

Certainly not a common sight with

sails from North: The luff on the

Warp F2012 8.6 has cracked.

Click the pictures to enlarge.

The crack is repaired by hand. An

aesthetic disaster - but much

stronger than letting a loft

do the job.

Click the pictures to enlarge.

2.

The North Platinum 490 cm bend curve evolution - and

implications for using new Platinums with older Warps.

I have to

say that reading the North homepage about the bend curves of

their masts grows increasingly surrealistic (see the bottom of

this page

http://www.north-windsurf.com/eng/nodes/display/pages/mast-technology).

No need to go into detail, but while a Platinum 2013 490 mast

typical had a bend curve of IMCS 15.8, my 2014 and 2015 Platinum

490 cm masts have been bend curve measured to around IMCS 17.8.

And my all new 2016 Platinum 490 mast has been measured to bend

curve IMCS 18.6!

Of course,

it's perfectly OK if the sails are designed around this kind of

Flex Top/Superflex Top bend curve masts - but why not tell us?

Why tell us that for instance the Neil Pryde masts can't be used

with the Warps because they're too Flex Top, when the truth is

that they are generally less Flex Top than the Platinum

490 and have bend curves very close to the Platinum 460? See

http://peterman.dk/masts-all-imcs01.htm.

Unfortunately, the Platinum 490 bend curve evolution caused me

to visit another brand (hopefully for a shorter period): When a

Platinum 490 cm 2013 mast (IMCS bend curve: 15.8) broke in my

Warp 9.2 F2013 I replaced it with a new Platinum 490 cm 2015

mast. However, the new mast turned out to be incompatible with

the sail. The lower part of the sleeve became very loose, but

even worse: The lowest camber simply couldn't stay put on the

mast. Different cambers from other brands and modifications of

North cambers were tried out, but in vain.

All this

happened mid-season, and as all Warps generally have to be

ordered pre-season at my place, I was forced to look for a

replacement sail from another brand. The choice fell on a Gun

GS-R 9.5, mostly because of the mast exchangeability between

North and Gun, but also because of a very competitive prizing

and a reputation for being attentive to the costumers.

How the Gun GS-R

9.5

sail performs compared to the Warps I'll

probably write a little about another time.

In the

meantime I've probably found a kind of solution on the problem

with the lowest camber falling off: Some Velcro fixed on the

camber and wrapped around the mast keeps the camber in place.

The solution works when rigged on the beach, but it hasn't been

tested on the water.

Facing incompability problems

with new (post-2013) Platinum 490

masts and older Warp sails?

A possible solution on "the

lowest camber falling off" issue.

Click the pictures to enlarge.

Receiving some new Warps F2016.

Generally,

the prizes for windsurf gear have raised to astronomic amounts

this year in my country. Rumours tell that the weak Euro

relative to the

We received

the sails at the beginning of October, and so far we've had some

4-5 sessions in far from optimal conditions. So, we certainly

haven't formed a firm opinion on the new Warps.

At the most

we've notice some sketchy outlines of their characteristics.

Performance

wise we've got the impression that the draft has moved somewhat

forward compared to our until now best Warps, the F2012 7.8 and

8.6. And perhaps I feel a tendency of a bit less stable drafts

compared to the F2012 Warps. At least the placement of the

harness lines aren't as obvious and distinct as I'm used to. But

still very, very interim impressions, gathered in gusty

conditions.

The sails

are very quick to get up in speed, and the top speed seems to be

comparable to the F2012 Warps (which is very good). In this very

early stage of the trimming process I have found it necessary to

lower the boom a couple of cm's to have my feet fixed securely

in the front straps. This is probably intended in the design, as

the boom cut-out seems to be placed a little lower compared to

the F2112 Warps.

The sails

feel a lot more compact than the F2012 and the F2013 Warps -

which in fact they are (a lot shorter luffs). So, not

surprisingly they feel somewhat more agile in the manoeuvres,

perhaps unless you're a light weight. They also feel a little

less direct and a little more "hesitating". They still

accelerate very good, but in a softer way than the F2012 Warps.

In the last

sessions we've had so far, the conditions were less challenging,

and when discussing our impressions we agreed on a

characteristic that's a little difficult to realize: The

average speed is very high. The F2016 Warps kind of don't

feel especially speedy in the peak moments, but when looking at

the surrounding sailors you're very competitive in the periods

when the conditions aren't ideal. And as the conditions are

seldom ideal for long periods, you have a good chance for being

in the lead after a couple of legs with the Warp F2016. Still

early days, but in a subtle way the new Warps seem to smooth out

the speed, compared to the more stiff on/off performance we've

got used to from earlier Warps.

My son is a

lightweight sailor, and the next time he takes his 8.4 on the

water he'll probably try it with an extended Platinum 460 mast

instead of the recommended Platinum 490 mast. To have an idea if

this is a

proper way to go, we've actually measured a Platinum

2015 460 mast (extended to 500 cm) and a Platinum 2015 490 cm

mast (extended to 500 cm), and the figures are:

Platinum

2015 490 cm mast extended to 500 cm (with 40 cm extension up in

the mast):

IMCS

stiffness: 28.7; IMCS bend curve: 17.9.

Platinum

2015 460 cm mast extended to 500 cm (with 15 cm extension up in

the mast):

IMCS

stiffness: 26.0; IMCS bend curve: 15.5.

The reason

he'll try the 460 cm mast setup with the sail is that the first

and only time he tried his Warp F2016 8.4 he found it a little

heavy in the jibes (in marginal wind, though).

As usual,

the first couple of sessions the cambers feel a bit sticky, and

you'll need a little wind to help them rotate. However, from

experience we know that after a few times on the water the

cambers rotate flawlessly. One of the 8.4's has been on the

water

4 times by now, and it already rotates as our good old

F2012s.

The all new

sleeve (made from a new non-stretch material) makes the sails

feel somewhat more crisp (camber rotation sounds like gun

shots!), and probably some of the performance advantages are

caused by this. However, the new sleeve construction also

demands that you rig the new Warps somewhat more gently than

older Warps. For instance, it's absolutely necessary to push the

cams (especially the lowest cam) in place from inside the

sleeve - contrary to what has been recommended in the pretty

old rigging manuals from North so far. If you try to push the

cambers in place from outside the sleeve you'll risk to damage

the non-stretch sleeve material severely. Oh - and of course

it's certainly not advisable to kick-rotate the cambers; and as

said, after a couple of sessions it's not necessary either.

As a matter

of fact we've already experienced the vulnerability of the

sleeve material: After the first (and so far only) session with

my sons all new Warp 8.4, it had some cracks around the lowest

camber. He was not aware that he had done anything bad to the

sail, and of course we at once asked a loft to repair and

strengthen the area. As a kind of insurance I told the local

importer about the issue - in case it should later happen to the

other new Warps too. And to my surprise the importer (having

been in contact with North) very quickly told me that it is

vital to rig the sails without pushing on the cambers from the

outside, as this may overload the sleeve material. And he pronto

changed the general North rigging instruction (for camber sails)

on his homepage. And a fortnight later North placed a new (and

revised) Warp rigging video on their homepage (https://www.youtube.com/watch?v=57czeE9zu1U&feature=player_embedded).

Both the

importer and North implicitly suggested that we had rigged

our

new Warps, following the old guidelines. And that this was the

cause for the cracks.

The

(potential) problem is that we've always rigged our Warps by

pushing on the cams from inside the sleeve, either through the

zipper openings or the boom cut-out, and so my son of course also did in

this case. And furthermore, the cracks showed on the port side

of the sail - that is to the opposite side to where the cracks

should arise, when you rig it zippers-up (starboard side up).

For now we just hope that my son by accident touched the sleeve too hard while sailing, and that this caused the cracks. But we'll be very observant if the problem will also show up on the other of the new Warps. I think that our Warps are from an early batch, and if so, North probably has the possibility to strengthen the lower part of the sleeves in future production series of the Warp F2016?

This may very well be the result if

you don't follow the new rigging

instruction on the Northsails

homepage: Cracks in the pretty

vulnerable sleeve material.

The actual damage did not

happen because of wrong

rigging procedure (see text).

Click the pictures to enlarge.

The cracked area repaired and

strengthened at a sail loft.

Click the pictures to enlarge.

|

Next

improvement of the Warps?

I think one

of the next steps for improvement among the race sail brands is

the centred placement of the batten pockets. As often is the

case (for instance the clew cut away, now adapted by all other

race sail brands), Neil Pryde is a forerunner here, presenting

the symmetric batten placement design in their RS EVO 6 series

in 2014. Hopefully the design will proliferate down the other

brands in the years to come.

*)

The classic

way to design a kind of symmetric sail is to place the

batten pockets alternately on either side of the sail. This is

also the case with the North Warps, where the longest batten

pocket (the one starting just under the boom cut out and ending

just above the clew) is placed on the port side of the sails.

The placement

of the longest batten pocket determines on which tack the most

important part of the leech of the sail "hooks" (flaps-down) or

"flips away" (twists, flaps-up). The more pressure you put on

the batten, the more pronounced the asymmetry.

Although

mostly a tendency (most felt with my Warp 7.7), on the new

Warps, I've noticed that on port tack the sails seem to have the

draft placed a bit more forward than on starboard tack. This

gives the sails a bit more stability on the port tack (the

twisting leech so to speak locks the draft in place forward) and

a bit more low end on starboard tack.

It's a

tendency that can be almost levelled out by the placement of the

harness lines. But unless you place the straps on your slalom

board a little asymmetric (on starboard tack a bit more

backwards to neutralize the backward draft of the sail) you'll

always risk the feel that your front foot on starboard tack is

sitting looser in the strap than on port tack. Unless, of

course, you lower the boom to get more pressure on the front

foot; but then it costs in early planing ... and so on. The

point is that a symmetric sail is a lot easier to trim. At least

in theory.

It's obvious that the hooking or

twisting leech issue has to be seen in connexion with the amount

of clew cut away, the placement of the clew eyelets and seam

shaping along the battens - but now it's becoming a bit

complicated. Here're some old (ignorant?) words about this

issue:

http://peterman.dk/windsurf-flaps-up01.htm.

It's

difficult to imagine how Neil Pryde has constructed the

symmetric placement of the batten pockets without creating a lot

of friction around the battens (making adjustments of a rigged

sail a hard work). But if it can be done without being too

vulnerable, it would be nice to have that feature in the future

Warps too.

And just to

put it in perspective: This issue with the Warps isn't nearly as

dominant as with some other race sail brands. For instance, my

2015 Gun Sails GS-R 9.5 sail way more asymmetric than any of my

Warps have ever done. Perhaps a result of much more clew cut

away, inappropriate placement of the clew eyelets (too low

relative to the dominant batten), simpler battens, looser batten

pockets, not ideal batten tension system, a seam shaping issue -

or just generally a way deeper sail?. The fact is that the very

asymmetric performance of my GS-R 9.5 caused me to place some

new foot strap plugs in my Fanatic Falcon 152, simply to place

myself further back on the board to get in line with the draft

on the starboard tack.

*)

For the

Severne Reflex race sails the Reflex system for years has

(partly) addressed the "asymmetric sail syndrome". And googling

the symmetric placement of battens it seems that the Simmer SCR

and the Avanti the Machine M-2 have entered this path too. It

also seems that Ezzy Sails has had their "Endobatten Shaping"

for years, but perhaps not for cambered sails(?).

|

A note on user reviews: Not a necessarily a punishment for the companies.

From a

reliable source I've got the impression that North isn't totally

satisfied with the reviews on this site. I think North should

be, and I'll try to explain why:

I think

there's a room between the babbling marketing folks and their

wagging tails (the obliging, but in reality say-nothing

sponsored sailors - and other professionals with interests in

biased views) - and the always negative,

over-critical

and not-constructive folks,

for whom nothing works and who see a conspiracy behind

everything.

It's in this

room most of us operate. Sometimes as small-talkers on the

beach, sometimes as readers and sometimes as writers. It's in

this room the better windsurf forums (for instance

http://www.seabreeze.com.au/forums/Windsurfing/) and the

better windsurf magazines (for instance the German "surf" mag.

and the French Planchemag mag.) are situated. Here lovers of the

windsurf sport exchange experiences and ideas, mostly cleaned

for irrelevant personal or corporate interests. In genuine

solidarity with other windsurfers the communication/reviews come

with honesty and modesty.

It's in this

room I try to give my small contributions to our sport. As an

(literally!) quite ordinary windsurfer - sailing perhaps a bit

too advanced equipment for my ability - I try to communicate

with other ordinary windsurfers who perhaps also sail equipment

on the border of their capability. I write what I find and

honestly mean, but I try to be fair and not too definitive in my

valuations. And unless finding very convincing evidence I

(usually) don't claim that what I've found is statistically

valid.

Why

should

companies like North welcome this kind of communication/reviews?

1.

Feed back.

All of us

know stories about bad, bad products that have partly destroyed

the reputation of a windsurf brand. Products, where bad designs

and flimsy "solutions" weren't changed for years, in spite of

massive warranty claims.

Of course,

it's costly to change a design, and probably it's not even

possible mid-season because the gear perhaps aren't manufactured

continuously, but in small series for stock. But that doesn't

explain why some companies don't rectify design and

manufacturing flaws for the next season. For instance, it simply

doesn't make sense that a major sail brand since 2004 for years

and years again didn't find a solution for the cracking luff

panels of their race sails. I mean, it's not rocket science to

strengthen a luff panel so that at least it doesn't crack for

the majority of the race sails. Other companies have had the

same problems, but to a much lesser degree. But more important:

If the race sails from other companies have shown similar

issues, they have (to my knowledge) rectified the problem the

following year. But not this major brand. Why?

I can only

find one explanation: Some companies simply don't receive real

feed back from the dealers and the importers. The

dealer/importer layer functions as a kind of "rockwoll layer"

between windsurfers with problems and the companies. The

companies simply don't get a realistic picture of the

dissatisfaction with their products among the costumers, because

the information is intercepted and handled in the

retailer/importer layer and never reach the company.

To follow the example, in my country the mentioned major brand have a very skilled (windsurf wise and commercial) importer, who apparently regard it as his task to "solve" the warranty problems by himself without (seemingly) involving the mother company. He takes action with much energy, very often by convincing the costumers that their claims are unfair and that they have to blame themselves.

Perhaps the

mother

company has defined his role like this, and probably the

company's very satisfied with his efforts.

But in fact it

shouldn't be. The prize for having a "wave-subduer" importer

might be that gear problems run for years without the company

having the full picture. And not having the full picture means

too little initiative to rectify.

In my place,

the recent years we've noticed a movement towards buying gear

from companies without a heavy (and expensive) importer/dealer

apparatus. That is companies that deal directly (or almost

directly) with the costumers. For instance, Gunsails has had a

big boost at my place, not only because of fine performance and

build quality at a very good prize, but also because of a

reputation for rectifying problems very quickly. To illustrate,

a couple of years ago Gun ran into a bad batch of masts from

their mast supplier. As soon as Gun realized the problem - which

I guess they did very quickly because of the direct

communication with their costumers - they mailed the buyers of

the bad masts and asked them to cut and return the 30 cm bottom

part of the masts. And within a fortnight the costumers received

some all new replacement masts. A pre-emptive action, before the

bad masts actually broke!

And a kind of

responsibility too seldom seen in the windsurf business.

The contrast to the years and years

again with

the

breaking Neil Pryde X9 masts without ANY action taken

by the company - except

from

blaming the costumers - is clearly

visible!

In general I

think the traditional chain from manufacturer to importer to

retailer to costumer is under attack. And not only because of

the on-line companies ability to cut the costs. Also - and more

important in this context - because of their ability to rectify

design and manufacturing flaws very quickly, based on the direct

communication with the users and costumers.

So,

companies with the traditional importer/dealer chain to the

users/costumers are exposed to the "rockwool layer" syndrome.

Especially for these companies the reviews

in the magazines, on

thge

internet forums and from individuals might be very useful,

perhaps essential - if they want the full picture.

2.

Choice of gear and decision making.

There's

another reason why the companies should be observant on the

unbiased windsurf communication/reviews: When I try to recall my

personal decision making process when buying windsurf equipment,

it's never based on a persuasive dealer or promotion stuff from

the companies. Most often I have a vague idea of my needs, so I

start to look for comparative tests in the magazines. Next step

is to search the internet for personal experiences (individual

writings and opinions on the forums). And if anyone on the beach

has some qualified input - or better: If anyone on the beach

show overwhelming performance without necessarily being a better

sailor than me - then of course I'm influenced.

The fact is

that I never choose equipment based on biased sources

like promotion stuff, dealer speech or team sailor babbling. Or

at least: Not that I'm aware of.

Of course I

read promotional stuff, watch promotional videos, listen to team

sailor stories, etc. But the interesting thing is the timing. On

a time-line, my need for biased information is always placed

after the

actual

decision making. When the gear's chosen and

ordered, I move into a phase of expectancy, mixed with a need

for confirmation: "Please tell me that I did the right choice."

And strange to say, the careful selected promotion stuff always

tell me

that

I've done the right choice.

If my

decision making procedure is representative for most

windsurfers, I think the windsurf companies ought to be

interested in the "un-authorized"

and un-biased

communication and reviews among windsurfers and use a less energy and money on

promotion that probably doesn't matter that much in the real

world.

So, my claim

is that what really moves us, is sober, balanced information.

And I don't see why serious windsurf companies shouldn't benefit

from user reviews, even if it contains fragments of

(constructive) critique. If a reviewer has a sober

critical/constructive approach,

perhaps

his/her

choice of

brand may have