Concave

October 2013.

This is how the bases of our Burton snowboards looked after we (my son

and I) had returned from our last 6 days trip to Hemsedal, Norway in

February 2013. We returned from the trip with the impression that our

boards had performed a bit more nervously than expected. Perhaps not

surprising when taking a closer look at the pictures (click the pictures

to enlarge).

Click the picture to enlarge.

Click the picture to enlarge.

As can

be seen, the

boards are extremely concave (the bindings are removed from the boards).

Before we actually measured for concavity, we ordered some base

flattener tools from SkiVisions (http://skivisions.us/).

But when we realized just

how

concave the boards were,

we gave up using the tools,

since (to our knowledge) the P-Tex layer

is just around

1.2 millimetres thick.

There

simply wouldn't be any P-Tex left around the edges

by the time the bases would eventually be level. So, what to do?

Well, you

could

of course

throw

away

the boards, and

sadly

that might

be the end of it. But

since ...

- replacement boards aren't exactly cheap,

- at least until our last snowboard trip we've been very pleased with the boards,

- our bindings (CO2

EST)

are dedicated to the

the bindings (we are, for good reasons, pretty reluctant to buy Burton boards again),

... we'll go to great lengths in trying to fix the concavity of the boards.

In the text below you'll find a few words on what the boards have been exposed to, followed by Burton's own comments, as well as a short discussion on what seems to us to be the most probable cause(s) for the concavity. Finally, you'll find a description of the steps that we've taken in a rather desperate attempt to remove the concavity from the boards.

What have the boards been exposed to?

Time of usage.

As

is evident from the

pictures, the boards

in question

are a Burton Supermodel 159 and a

How

have the boards

been used and stored.

I'm 63 years old and

have been snowboarding for 12 years. My son

is 25 years old and has been

snowboarding for 8 years. We're certainly no daredevils

and

mainly visit the groomies with

some very short excursions to the non-prepped

areas. Here's a headcam video from our last trip,

to show

that we

are not

mistreating our

snowboards:

https://vimeo.com/62104509;

"Mikkel" is the Supermodel rider and the headcam man is the Supermodel X

rider.

When not in use, the

boards have been kept dry in room temperature. Coming home from our

trips we always do an

interim preparation

of the boards

for the next season (drying the boards, preparing the rails and bases).

The bindings have not been removed during the storage period.

Contacting

the retailer and the Danish importer to

get an idea of what might have happened.

Contacting our

retailer (

Our retailer tried

again ("...

I

hope you can do better than this!"), but in essence

he

only got a repeat

of the same answer ("...that's the closest I can get

...").

In fact it

could have been a kind of answer - if

But

Developing some theory about what might have happened.

To

outline

some plausible

causes

for the

Supermodel/Supermodel X

concavity,

we first have to find out what could

not

be the cause.

1) It's not impossible, but not probable either, that the boards were manufactured at the same time. We're not even sure if the boards

were manufactured at the same facility. And according to the specs, the boards are not made from quite the same materials (but

close).

So,

because of the presumably lack of identity between

manufacture time, manufacture facility and board material it's

most likely that the boards were OK when they were sent

to

2)

To check

whether

concavity

is common in new boards,

we controlled

some new boards (around 50, most

our

retailer. Non of them had the slightest hint of

concavity.

So, it's

most likely that the boards were OK when we brought them home from our

retailer. Perhaps underlined by the fact that the boards

were bought at the same place - but not at

quite

the same time.

3) The boards have been kept in a dark, dry, temperate room between our snowboard trips. Temperate means between 15 - 25 degrees

Celsius.

So, the

boards have never been exposed to excessive

humidity, heat or the like. Yes, the boards have been exposed

to

cold (down to approx. -20 degrees Celsius) on our trips, but

we

suppose

that's what the snowboards are built for

...

4)

The boards have never been in contact with any base or edge grinding

machine, structure machine, waxing machine, or the like.

The boards have exclusively been prepared by hand with a Toko waxing iron (always in motion!), a plastic scraper and some Burton

and Toko

edge devices. And the waxes used have almost always been from the Swix

LF series.

So, the

boards have always been carefully prepared,

both when returning from our trips and just before departing

on one.

5) When transporting the boards to the Norwegian destinations, they have been kept in padded DaKine board bags in a roof box on

our car.

So, the

boards have been transported carefully, lying loose and

protected in padded board bags in a roof box.

But then, what

might

have

triggered

the concavity?

1)

When searching the internet it seems that some guys (claiming to have

been working within the industry for years) argue that "

boards are notorious for poor quality construction", and that "80% of the (Burton) boards that came through our shops were

borderline or completely untuneable because the base becomes concave"

(http://www.bikeforums.net/archive/index.php/t-74699.html).

We haven't got the faintest idea if this is true or just a rumour. Perhaps the dominance of a brand will always result in such

accusations, or perhaps lots of people have actually experienced massive quality problems. We don't know. But at least it seems that

it's not quite

unthinkable that some

2) Our bindings (CO2 EST) have always been fixed to the boards. Tightly, but certainly not by using excessive force. Of course, the

bindings have been loosened

when tweaking with the stance and angles, but they've

never

been removed for a longer period of time.

Is it feasible that the continuous pull in the channels from the bindings could have pulled the boards concave? We've all seen what

always happens under the boards that use the standard 4 screw mounts ("binding suck"), but here we're talking about channels in

almost 2 thirds of the running length of the boards. If the channels are weak and/or haven't been solid located in the boards it seems

(to us, at least) to be feasible that concavity in almost the whole length of the bottom of the boards could have developed. So there's

good reason to take a

closer look at the ICS mounts:

3) The boards are from the first (pre-2011) generation of ICS. The following generation of ICS seems to be a little more robust and went

from M5

bolts/mutters/thinner tracks to M6 bolts/mutters/thicker tracks. Why did

realized that the first generation of ICS were too weak to withstand the pull from the binding with concavity as a consequence?

Replacing the concave boards with new Burton snowboards?

If the

cause

of

the concavity

in

our boards

turns out to a mounting system

that is too weak (a system that

for whatever reason was beefed up from 2011 and onwards),

then there's

no apparent reason not

to replace our Supermodel and Supermodel X with new Burton snowboards

that have the post-2011 ICS, for

instance a couple of

Family Tree Juice

Wagons.

But two things hold us back:

Firstly, until we get a

confirmation that the (now dismantled) weak(?) ICS has been the main

cause for the concavity, we'll have to assume that all

And secondly, the arrogance from Burton (or the Danish Burton importer?) in refusing to give us a hint as to what can trigger a concave Burton snowboard ought not to be rewarded. Meaning that just visiting our retailer to buy a couple of new Burton boards in replacement of boards that have been destroyed from within 12-18 days in the white stuff is not the right way to go.

So, although we've owned several other Burton snowboards over the years (T6 (4 screw mount), Custom X (4 screw mount), Barracuda (post-2011 ICS mount)) - and have been very satisfied with the performance and sturdiness of the boards - unfortunately we'll have to look elsewhere in the future.

An attempt to

save our boards.

As stated,

it's impossible to remove the concavity

in our boards by using grinding

tools, as they'll just grind through the P-Tex (and probably

most of

the steel edges as

well) before the boards

are flat. The other option, of

course, is to try to press the boards into shape again. Perhaps it's a kind

of "mission impossible", but we've given this option a try.

In essence, we've

made a couple of

casts (kind of 3D prints, moulds) of the edge areas of the bottoms of the boards (in

plywood, strengthened with carbon weave). Between the edge-supporting

areas of the casts some material (plywood) has been removed, so that

when pressing very hard in the middle of the boards (by

clamps)

it's possible to press them into a convex shape.

Simply applying clamps directly on top of the boards of course exhibits unacceptable point loads, so to avoid this we've also made a couple of "casts" (again from plywood, strengthened with carbon weave) of the middle sections of the boards. So when squeezing the boards between the "casts" it's hopefully possible to bring the boards back into their original shapes by counteracting the concavity by squeezing the bottoms into a convexity. If we're very, very lucky the snowboards will have regained their original flat shape when we release the clamps. Some "check holes" are drilled into the bottom "casts" to estimate just what goes on shape-wise between the casts.

Hopefully the

pictures clarify a little.

The casts.

Click the picture to enlarge.

The bottom casts lying

ready.

Click the picture to enlarge.

The boards in place on

the bottom casts.

Click the picture to enlarge.

The top casts placed

on the boards.

Click the picture to enlarge.

Squeezing the boards

between the casts using clamps.

Click the picture to enlarge.

The same - upside down.

Click the picture to enlarge.

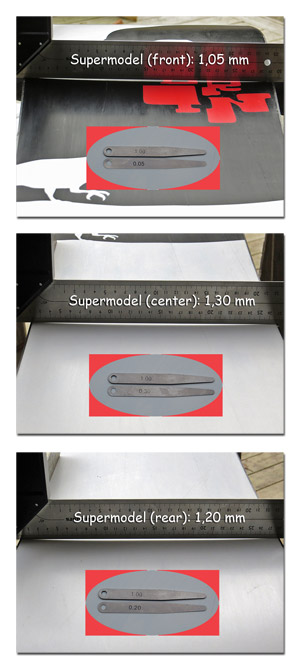

Controlling the

squeezing/shape of the bases using a vernier gauge in the "check holes"

(Supermodel).

Click the picture to enlarge.

Controlling the

squeezing/shape of the bases using a vernier gauge in the "check holes"

(Supermodel X).

Click the picture to enlarge.

The boards have now

been squeezed for a couple of months, and soon we'll check what (if

anything) has happened. If the squeezing has had no effect,

perhaps we'll try squeezing the boards back into forms again,

this time

placing

them in a hot environment (a

sauna?)

for

a few hours. It may ruin the boards, but

then again, aren't they

ruined already?

Snowboard

concavity, does it matter at all?

As

is hopefully understood, we're not advanced snowboarders at all, and it's hard for us

to tell just how much better a flat snowboard will perform compared to

our concave snowboards. But when searching the internet for opinions on

this issue,

it's pretty obvious that even

a

smaller amount of concavity is

considered

to be

something that must

be avoided or otherwise

corrected. In our

case, we're not talking

about a smaller amount of concavity, and correcting it by conventional

means

is unfortunately not

an option.

So we'll sadly

have to trust the words of wiser

people, for instance Scott Firestone from

"alpinecarving", when he says:

"A concave base is a nightmare, because your edges will keep catching

when you try to initiate a turn or glide on the flats." (http://www.alpinecarving.com/tuning.html).

Update, spring 2014:

After a couple of

months of squeezing the boards they

have been

released from their prison. And after further a couple of weeks of

letting them lying without pressure to allow for any possible

compensating memory to work, it

is time to

valuate.

And in fact the

pressure has

worked - to some degree. There

are variations along the

lengths of the boards, but the general picture

is that the middle of

the boards (along the centre

lines)

is

almost squeezed back in position, while in the areas in between the

centre lines and the rails there still

re

some concavity. In fact the cross sections of the boards can be described as the

contours of gull wings.

Will the boards now

be worth using? Well, we'll

probably never know. Not being in a position to forsee

how the squeezing experiment would develop

and

consequently

how the boards would

react when actually hitting the snow, we had to invest in a couple of

new boards (and bindings) - just to be sure to have some quality time in

the white stuff. And of course this time we didn't opt for Burton

products, as we have lost a fair bit of confidence in their "the Cannel"

mounting system - and in the ability of Burton to back up their products

by at least producing a kind of explanation about what could possible

have gone wrong with our boards.

Oh, and our new

boards are a couple of Nidecker Megalights with traditional binding

mounting inserts, equipped with Nitro Blackhawk and Salomon Caliber

bindings.